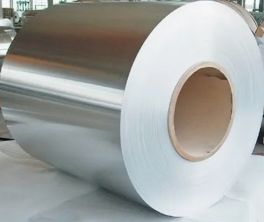

We supply a wide range of rolled copper foils, in a variety of different grades to meet customer requirements, including Cu-ETP, Cu-DHP and CU-OF (oxygen free).

Why choose our copper foil?

Our high-quality copper strip is a versatile and essential component in the realm of heat exchangers. Renowned for its exceptional thermal conductivity and malleability, copper foil ensures optimal heat transfer efficiency within various industrial and commercial applications. Its thin and flexible nature allows for seamless integration into complex designs, promoting effective heat exchange. between fluids while maintaining durability and reliability

Applications

Our copper foil/strip can be used in an array of different applications, from air conditioning systems to electronics cooling solutions, copper foil plays a pivotal role in enhancing energy efficiency and overall performance. More specifically, an example of this would be it's use in heat exchangers.

Copper Foil/Strip Technical Information

| Grade | C106 / Cu-DHP / CW024A | C101 / Cu-ETP / CW004A |

|---|---|---|

| Chemical Composition | Copper (Cu) – min 99.90% Phosphorus (P) – 0.015% - 0.040% | Copper (Cu) – min 99.90% Oxygen (O) – Max 0.04% Silver (Pb) – Max 0.005% Bismuth (Bi) – Max 0.0005% |

| Conductivity | - | Minimum 98.3% |

Material Condition

| Temper | R220/H040 = ‘O’ Soft | R240/H065 = ½ hard | R290/H090 = Hard |

|---|---|---|---|

| Thickness | 0.025mm - 0.50mm | 0.025mm - 0.50mm | 0.025mm - 0.50mm |

| Width | 5.0mm - 520mm | 5.0mm - 520mm | 5.0mm - 520mm |

| Hardness | 40-65HV | 65-95HV | 90-110HV |

| Tensile Strength | Min 220 - Max 260 MPA | Min 240 - Max 300 MPA | Min 290 - Max 360 MPA |

| Yield Strength | Max 140 MPA | Max 180 MPA | Max 250 MPA |

| Elongation | Min 33% | Min 8% | Min 4% |

| Density | 8.9g/cm3 approx | 8.9g/cm3 approx | 8.9g/cm3 approx |