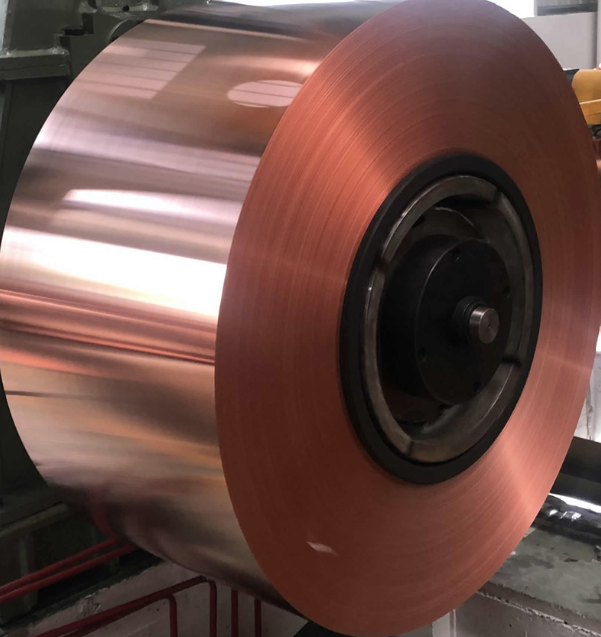

Our hydrophobic coated Aluminium foil can be produced plain or with a gold, blue or black hydrophobic coating. The hydrophobic coating not only increases the thermal conductivity of the foil, it also increases the resistance to corrosion by at least 300%, when compared with plain aluminium foil. This makes hydrophobic coated foil the perfect material for those looking to produce a more efficient heat exchanger.

Applications

Hydrophobic aluminium foil makes the fin surface hydrophobic, preventing condensate from adhering this improves life span of air conditioners, improves ventilation and refrigeration efficiency and reduces power consumption.

Hydrophobic coated Aluminium Foil Technical Information

| Thickness | Width | Internal Diameter | External Diameter | Alloy |

|---|---|---|---|---|

| 0.08mm - 0.50mm | 40mm-1400mm | 75mm, 150mm, 200mm, 300mm | 100mm - 1400mm | 1050, 1100, 1200, 3102, 8006, 8011 |

Grade - 8011

| Temper | ‘O’ – soft | H22 | H24 | H18 |

|---|---|---|---|---|

| Tensile strength | 80-110 MPA | 100-130 MPA | 115-145 MPA | ≥160 MPA |

| Yield strength | ≥50 MPA | ≥65 MPA | ≥90 MPA | / |

| Elongation | ≥20% | ≥16% | ≥12% | ≥1% |

Grade - 8006

| Temper | ‘O’ – soft | H18 |

|---|---|---|

| Tensile strength | 90-140 MPA | ≥170 MPA |

Packing

- Coils on pallets, in wooden boxes

- Stackable for easy storage and transportation.

Quality

We endeavour to provide all customers with highest standard of quality across our full range of products, and that is why all material supplied is produced in line with the ISO 9001 Quality standard certification.