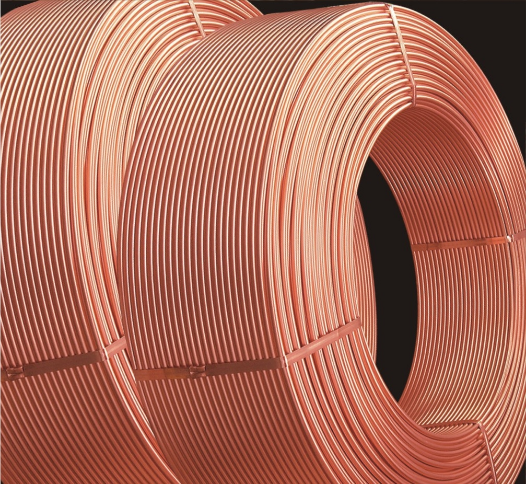

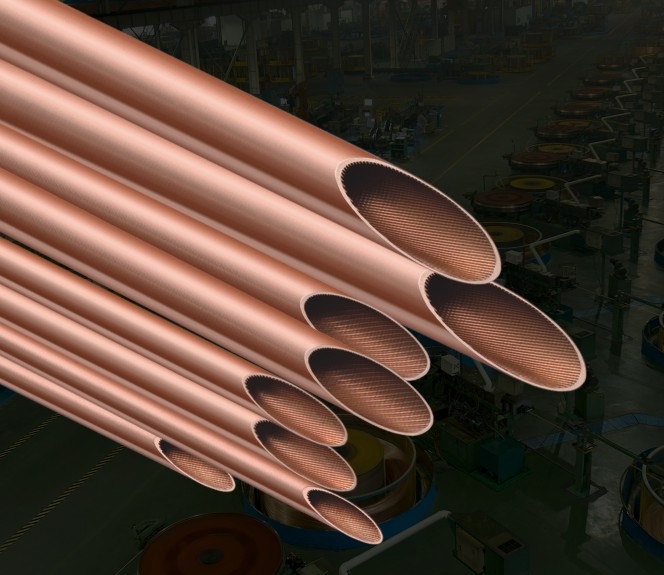

Copper fin tubes are formed by a rolling process, which raises fins in a continuous spiral on a straight length of tubing. The increased surface area of finned tube ensures optimal heat transfer.

| Outer Diameter | Wall Thickness | Length | Temper | Tensile Strength | Elongation |

|---|---|---|---|---|---|

| 8-30mm | 0.6-2.0mm | ≤18000mm | Finning part: cool process Without fin: Soft | 205Min MPa | 35% Min |