Our Alloy '5052' aluminium foil is a combination of both Aluminium and Magnesium (AlMg foil) AIMg foil has increased corrosion resistance to seawater, and increased strength, making it ideal for marine and industrial applications, such as pressure vessels/tanks, as well as in heat exchangers

Application

Aluminium alloy 5052 has very good corrosion resistance to seawater and marine and industrial atmosphere.

Marine Aluminium Foil Technical Information

| Thickness | Width | Internal Diameter | External Diameter |

|---|---|---|---|

| 0.08mm - 0.50mm | 1400mm | 75mm, 150mm, 200mm, 300mm | 100mm - 1400mm |

Grade - 5052 Aluminium Foil

| Temper | ‘O’ – soft | H22 | H24 | H18 |

|---|---|---|---|---|

| Tensile strength | 170-215 MPA | 210-260 MPA | 230-280 MPA | ≥270 MPA |

| Yield strength | ≥65 MPA | ≥130 MPA | ≥150 MPA | ≥240 MPA |

| Elongation | ≥12% | ≥5% | ≥4% | ≥1% |

Quality

We endeavour to provide all customers with highest standard of quality across our full range of products, and that is why all material supplied is produced in line with the ISO 9001 Quality standard certification.

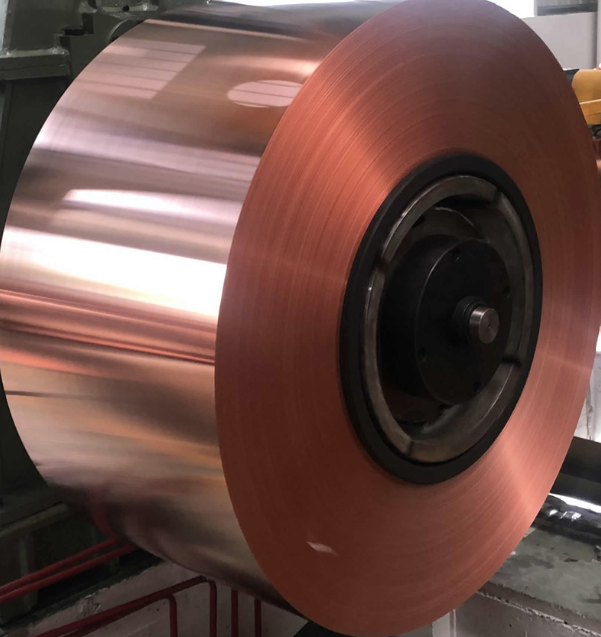

Packing

- Coils on pallets, in wooden boxes

- Stackable for easy storage and transportation.

Why to choose our foils

Our plain foil is the most cost effective foil for use in heat exchangers, with both our 5052 and coated aluminium foils being slightly more expensive premium options. This is due to the strength, durability and thermal conductivity being heightened in both our 5052 and coated foils, protecting against corrosion of the fin, and further lengthening the life of the heat exchanger. Furthermore, all of our foils are produced in line with the standards of ISO 9001, to ensure our material is of the best quality.